Predictive asset management is an approach that transforms how enterprises manage their IT assets by leveraging real-time signals from connected devices to predict device failures and optimize performance before any major setbacks occur.

By leveraging IoT data and advanced analytics, businesses can reduce downtime, extend asset lifecycles, and cut management costs.

Integrating these insights into a robust enterprise IT asset management strategy ensures smarter, more cost-effective technology operations.

With the power of predictive asset management, enterprises can now enhance Device Lifecycle Management (DLM) by leveraging AI-driven insights for smarter hardware asset management.

This approach not only streamlines IT asset management (ITAM) but also optimizes device refresh cycles and minimizes IT asset depreciation, ensuring sustained IT lifecycle optimization.

TLDR;

- Real-time sensor data and AI-driven analytics predict device issues, enhancing IT asset performance and lifespan.

- Predictive maintenance reduces costs by minimizing downtime and optimizing device refresh cycles effectively.

- Automated workflows across DLM stages, planning, procurement, provisioning, maintenance, and decommissioning.

- Proactive issue detection and compliance checks improve security and user experience across device fleets.

- Unduit’s platform integrates predictive tools with ITAM for seamless asset management and actionable insights.

Unlock seamless IT asset management with Unduit.

Discover how our platform automates the entire IT asset lifecycle, from procurement to disposal.

Book a Demo!What is Predictive Asset Management?

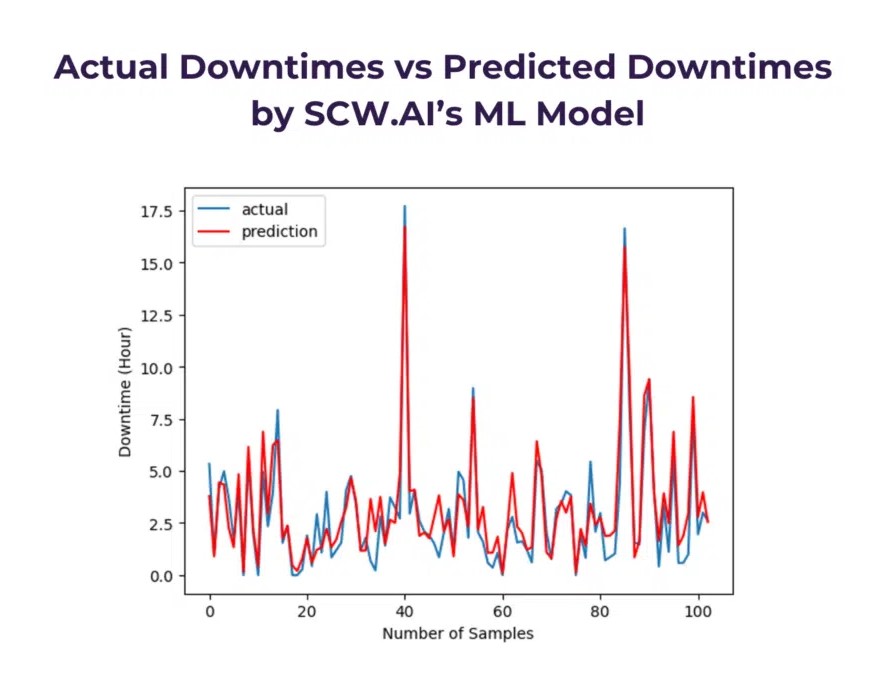

Predictive asset management builds on condition-based monitoring to optimize the performance and lifespan of equipment by continually assessing its health in real time. By collecting data from sensors and applying advanced analytical tools with help of predictive machine learning algorithms to asses the health of each it asset in your fleet.

Predictive asset maintenance can identify, detect, and address issues as they occur, as well as predict the future state of equipment depending on the work load, and so does help in reduce risk prior to any major damage. The key is providing the right information to the right people at the right time to make the right decision.

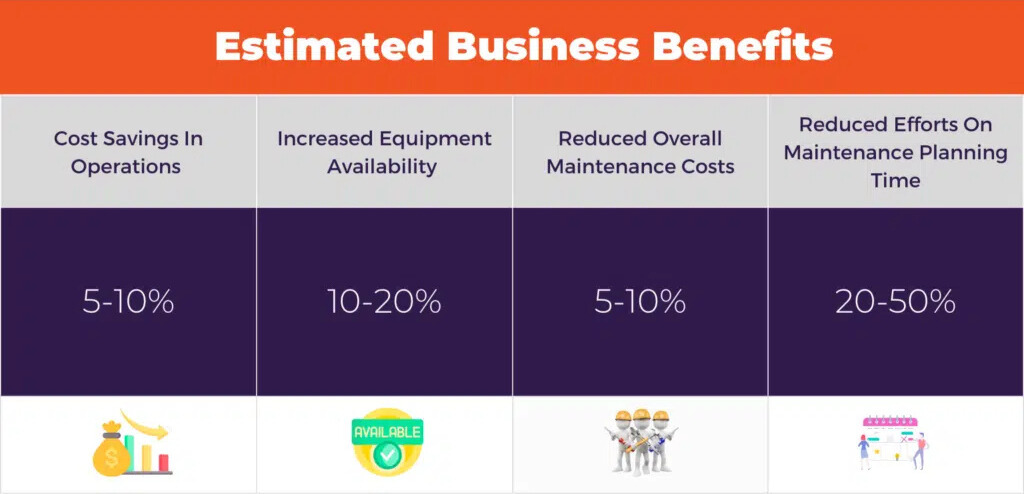

Business benefits of predictive asset management

Predictive asset management helps businesses improve efficiency, reduce costs, and enhance safety by proactively addressing potential issues before they cause significant problems.

Key concepts

- IoT (Internet of Things): IoT sensors collect real-time data on equipment condition and performance.

- Cloud-based analytics: Data is transmitted to the cloud for analysis using machine learning algorithms.

- AI & machine learning: Identifies patterns and predicts future failures or bottlenecks.

- Anomaly detection: Algorithms identify deviations from normal behavior, indicating potential issues.

- Condition monitoring: Sensors continuously monitor equipment health and performance.

- ITAM/DLM platforms: Integrate with tools like Unduit to act on predictions automatically.

5 Key Steps to Get Started

Building a robust predictive asset management system doesn’t happen overnight, but with the right steps, any organization can begin transitioning from reactive IT to proactive operations.

1. Audit Your Current Setup

Take stock of your existing ITAM infrastructure, device fleet, and data sources. Identify areas where performance, compliance, or costs are falling short.

2. Centralize Device Data

Solidify your performance metrics, usage patterns, and damage histories into one centralized system. This data foundation is key to enabling predictive insights.

3. Select the Right Platform

Choose a DLM or ITAM solution, like Unduit, that supports predictive analytics, real-time monitoring, and AI automation. Ensure it integrates well with your existing tools.

4. Launch a Focused Pilot

Start with a manageable use case, such as remote field staff or sales teams, to test predictive workflows and gather initial results.

5. Review, Optimize, and Scale

Evaluate the asset outcomes. Did you reduce downtime? Did you avoid any failures? Use this insight to refine your predictive models and expand across more departments.

The Shift from traditional to predictive lifecycle management

In traditional IT setups, teams rely on fixed device refresh cycles and manual asset health reporting, often leading to delayed preemptive measures and unexpected hardware failures. Predictive asset management uses real-time diagnostics and AI models to anticipate device needs, automate actions, and optimize the IT asset lifecycle for more efficient hardware asset management.

How does Predictive management fit across the lifecycle management stages?

- Planning: As per performance trends and role-specific usage data, to forecast future work needs accurately.

- Procurement: This helps to replace guesswork with data-driven decisions on what to buy and when to buy it.

- Provisioning: Automate software/hardware configurations tailored to predicted user needs.

- Maintenance: Proactive alerts, automate patching, detect slowdowns early, and resolve issues before users are impacted.

- Decommissioning: Identify underperforming or end-of-life (EOL) assets ahead of time and plan secure retirement.

Benefits of predictive asset management in ITAM

1. Reduce Costs

Predictive asset maintenance helps It managers minimize unplanned downtime and optimize device refresh cycles, resulting in significant savings on unnecessary replacements and operational inefficiencies.

2. Limit Disruptions

Proactive issue detection through enterprise device monitoring enables teams to resolve problems before they impact workflows, reducing downtime and keeping productivity high.

3. Boost Productivity

By automating routine asset maintenance and optimizing workload distribution, predictive IT management supports uninterrupted operations and increases IT team productivity.

4. Enhance Device Lifespan

Predictive analytics identify wear and tear early, allowing timely servicing or replacement, which extends device lifecycle and maximizes ROI within the device lifecycle management process.

5. Improve Security and Compliance

Automated compliance checks and timely patching reduce security risks and support regulatory requirements, reinforcing robust hardware asset management.

6. Improve User Experience

Devices remain reliable and responsive, leading to fewer helpdesk tickets and a smoother user experience.

7. Support Quality Control

Predictive insights help IT managers detect performance anomalies across device fleets, enabling early intervention before minor issues escalate.

Real-World use cases of predictive asset management

- Fail-Fast Flagging: AI-Assisted predictive models identify laptops with declining battery health and rising heat signs. IT managers are alerted to proactively replace these devices before device damage disrupts workflow.

- Onboarding Forecasting: AI models provide historical onboarding data to analyze and accurately forecast device demand based on upcoming hires. This helps procurement teams pre-order equipment, ensuring no delays in new employee setup.

- Mobile Fleet Optimization: Predictive tools spot aging mobile devices that are slowing down and consuming more resources. These devices are replaced or reassigned before impacting field team productivity.

- Smart Refresh Planning: Instead of replacing all devices on a fixed schedule, predictive analytics recommend which devices actually need upgrades, optimizing refresh budgets while improving performance.

- Security Vulnerability Detection: Predictive algorithms scan devices for patterns of outdated software or frequent crashes that signal possible security gaps, triggering proactive patching or isolation protocols.

Challenges to keep in mind

Predictive asset management offers significant value for enterprises in ITAM, but it comes with key challenges. Enterprise outcomes depend heavily on clean, consistent, and reliable data, poor data quality limits predictive accuracy.

Integrating predictive tools with existing enterprise ITAM platforms, ERP systems, and workflows can be complex, often requiring development resources or API support. Cost considerations also matter, both in terms of infrastructure investment and ongoing operational expenses.

Moreover, enterprises must upskill IT teams to interpret and act on predictive insights effectively. Finally, while predictive systems deliver fast answers, organizations must ensure transparency and trust in how those results are generated, especially in highly regulated industries. That’s why enterprises should approach predictive asset management as a strategic initiative, not a quick fix.

Explore 100+ Plug-and-Play Integrations

Deliver bottom-line procurement results faster with a consolidated dashboard integrating HRIS, MDM, and IT tools at one click.

Conclusion

Predictive asset Management is more than a trend. It’s becoming the foundation of modern ITAM. As device ecosystems grow more complex, using data to get ahead of issues will separate reactive teams from truly resilient ones. For enterprise IT leaders, the future isn’t just managed. It’s predicted.

FAQ’s

What technologies support predictive maintenance?

Technologies such as IoT sensors, AI/ML algorithms, cloud computing, big data analytics, and digital twins play a major role in enabling predictive maintenanc

What is the role of AI in maintenance management?

AI can predict equipment failures and generate maintenance insights faster and more accurately than older technologies. In doing so, AI helps companies reduce machine wear and tear and unplanned downtime.

How can AI be used in maintenance?

Companies can use AI to monitor machinery conditions, detect anomalies, avoid equipment failure and outages, and prioritize and schedule maintenance. AI helps in security, user experience, and detect issues early, enabling IT managers to maintain a cost-effective asset environment.

How is machine learning used in predictive maintenance?

Machine learning algorithms can predict when factory equipment will deteriorate, fail, and require repair or replacement. They’re key to AI-driven predictive maintenance solutions.

How does Predictive Maintenance differ from other maintenance strategies?

Predictive asset maintenance differs from other strategies by using real-time data and analytics to monitor equipment health and anticipate failures before they occur. Unlike reactive maintenance, which waits for breakdowns, and preventive maintenance, and which schedules tasks at fixed intervals regardless of actual need.

What are the benefits of Predictive Asset Management in ITAM?

Predictive Device Management in ITAM reduces costs by minimizing downtime and optimizing refresh cycles. Proactive monitoring limits disruptions, while automation and analytics boost efficiency and extend device lifespans.

What is the future of predictive maintenance with AI?

Future trends include deeper integration with digital twins, automated decision-making, self-healing systems, and broader adoption across industries